Here's a glimpse of our kitchens where we make our candies, jams, and jellies!

1) The kitchens of Alaska Wild Berry Products: The four kitchens are called the Jam and Jelly Kitchen, Hot Kitchen, Candy Kitchen, and the Molding Room. You can watch all four kitchens in action through the viewing windows in our store.

2) Molding: Chocolate candies are made in molds filled with liquid chocolate that solidifies when it cools.

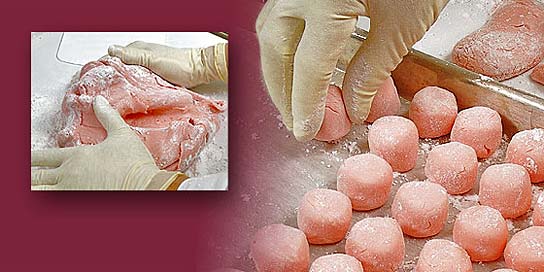

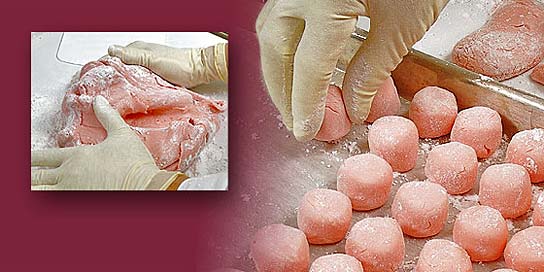

3) Cream centers: Bulk creams are made in the Hot Kitchen then hand-rolled and shaped into round centers that will be enrobed in chocolate.

4) Enrobing: Enrobing is the term for coating candy centers with chocolate.

5) Hand decorating: All our candies are hand decorated with a design that identifies each flavor.

6) Hand packaging and wrapping: The candies are individually selected and placed into each box.

7) Making our delicate meltaways: The ingredients for the meltaways are heated and stirred in the copper kettle. When the candy is ready, it's poured onto the cooling table and cut by hand using a roller cutter.

8) Making candy popcorn: All the coatings are prepared and poured onto freshly popped popcorn in the copper kettles and mixed. The warm popcorn is poured onto special tables to cool and harden. Some flavors are also mixed with chocolate.

9) Jelly center chocolates: Wild berry juice is cooked with other ingredients. The liquid 224°f candy is poured onto the cooling table, spread to an even thickness, and cut into individual squares with the tool we call The Claw.

10) Fudge bits: After the candy has been cooked, other ingredients such as nuts can be added. The candy is poured onto the cooling table and slabs of fudge are run through a cutting machine that slices it into pieces.

11) Black Bear and Klondike Toffee: Liquid 312°f toffee is poured onto a cooling table, spread into a metal frame, and cut into squares to be used for either Black Bear Toffee Crunch or our chocolate-covered Klondike Toffee.

12) English Toffee: Liquid 312°f toffee is poured onto a cooling table, spread without a frame, and cut into slabs that are coated with chocolate and dusted with ground almonds. Then they're flipped over and coated on the other side.

13) Caramel Centers: The caramel is agitated and cooked in a machine called a Fire Mixer then poured onto the cooling table to solidify and be cut into individual squares.

14) Caramel Turtles: Caramel is made the same way as for the caramel centers but this time it's poured into the Caramel Depositor. The depositor drops dollops of caramel onto trays of nuts. When cool, these candies are removed from the trays and enrobed in chocolate.

15) Cream Centers: Hot liquid sugar is mixed with fruit purees. As the sugar cools with constant agitation, it crystallizes and changes color and texture until it forms a cream. The bulk cream is hand rolled in the enrobing kitchen before it is coated with chocolate.

16) Grinding fresh berries: We use locally harvested and gathered lingonberries, salmonberries, mossberries, rose hips, blackberry, raspberries, high bush cranberries, black and red currants, wild blueberries, organic rhubarb, and fireweed blossoms.

17) Juicing fresh berries: Berries are heated to help release all their natural juices before being strained and used for candy or jelly.

18) Sourdough Sauce: Ingredients are added to our signature Sourdough Sauce that has been made by Alaska Wild Berry Products since 1946.

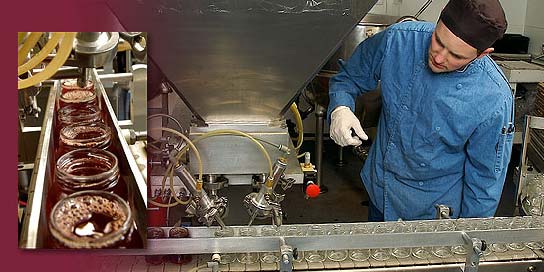

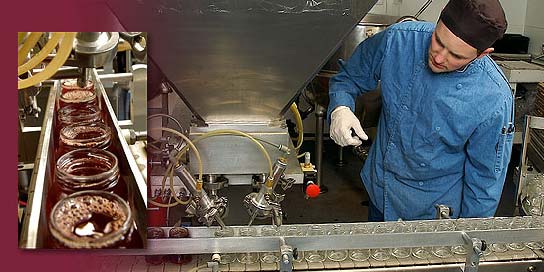

19) Filling the jars: Hot jams, jellies, and sauces are pumped into the hopper then they are deposited automatically into jars.

20) Capping: The jars are capped automatically then flipped over to heat seal the lid to the jars.

21) Ready for Market: We hope you have enjoyed our little walk through the kitchens. Although we have only touched the surface, it should give you a better understanding of what we do here. Thanks for joining us!